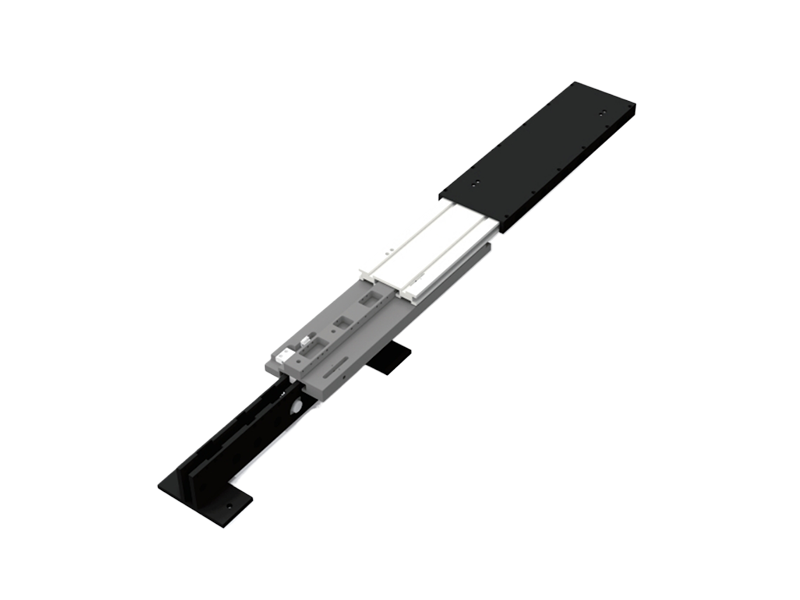

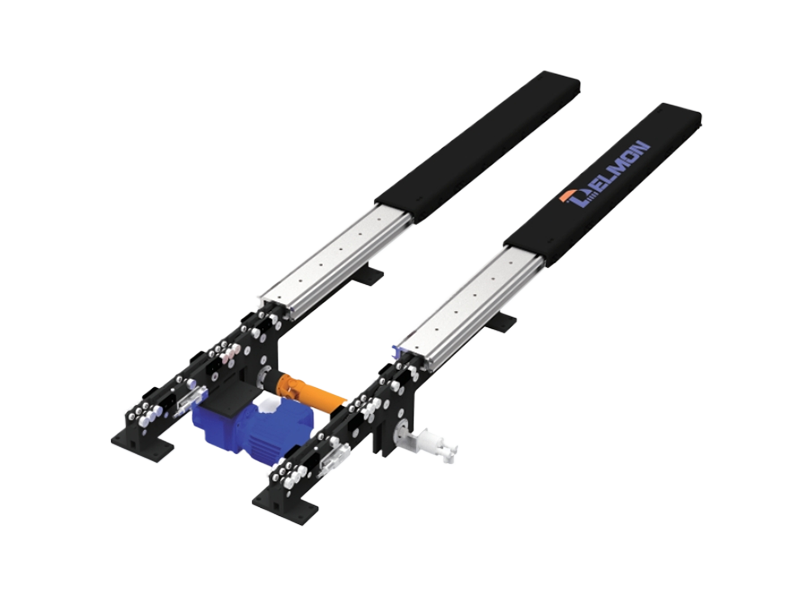

Roll C4

Category:

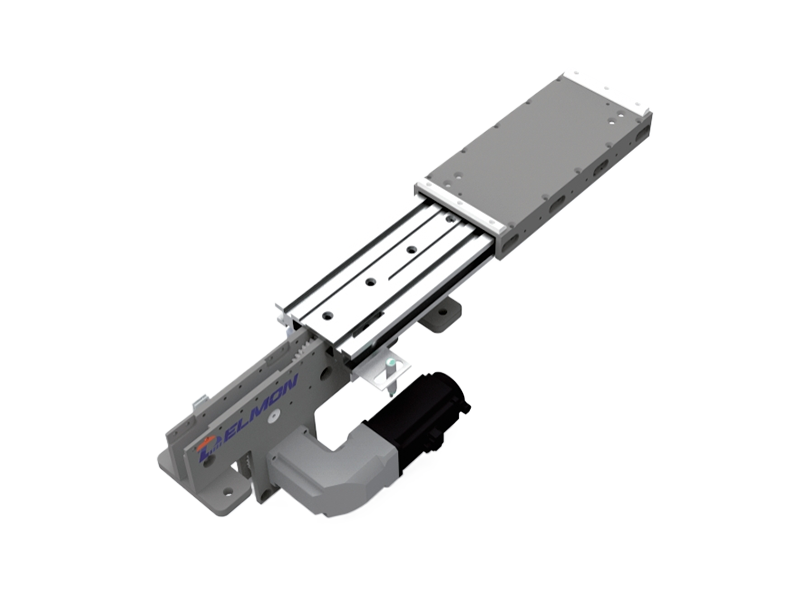

Overview:Breaking through the limitations of traditional forklift fixed wheelbase, using fully electronic variable distance technology to achieve rapid switching of multi-specification carriers, providing flexible handling solutions for multi-category warehousing scenarios. Widely used in automated storage and retrieval systems (AS/RS) and other intelligent warehousing fields.

Consultation

Consultation

Product Details

Intelligent Angle Adaption - All-Scenario Roll Handling Expert

Specifically designed for irregularly shaped rolls such as steel rolls, paper rolls, and fabric rolls. Combining an inclined tine structure with multi-material surface treatment technology to achieve highly compatible and low-damage flexible handling.

Product Features

Inclined Tine Design | The tines form a fixed angle of 5°-25° according to the diameter of the roll, optimizing the force distribution on the contact surface. Compared to flat tines, the lateral pressure is reduced by 150%, and the roll deformation is <0.3%. |

Graphite Alloy Pads | Key load-bearing pads use graphite alloy, increasing wear resistance by 3 times, with a lifespan of >100,000 cycles. |

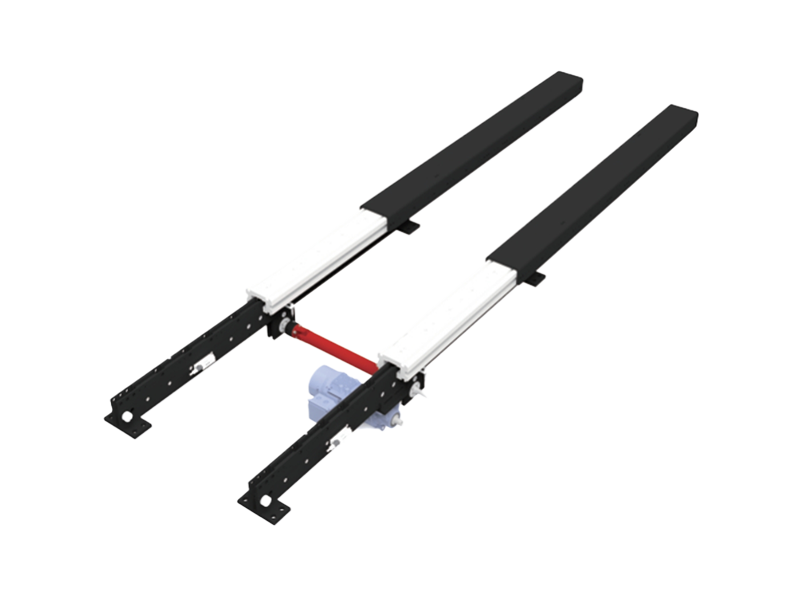

Multi-Scenario Adaption Solutions | Mid-Support Rack: Inclined tines + Adaptive Angle |

| Cantilever Rack: M-shaped support plate + Two-way locking mechanism | |

| Mixed Storage: Lingju Flex variable spacing system (adjustable spacing 300-3000mm) | |

Surface Treatment Process | Paper/Steel Rolls: Polyethylene resin coating (friction coefficient μ=0.6-0.8) |

| Steel Wire Rope: Pre-hardened tool steel (Toolox) or wear-resistant Hardox steel | |

| Carpet/Film: Silicone rubber flexible pad (anti-slip and anti-scratch) |

Selection Suggestions

Industrial Scenarios | Configuration | Empirical Results |

Steel Hot Rolling Workshop | Pre-hardened tool steel + Liquid cooling system | Continuous operation in a 150℃ environment, roll temperature conduction loss ↓70% |

Paper Industry Logistics Center | Resin-coated tines + Silicone edge protection | Zero burrs in paper roll handling, 140% warehouse density |

Multi-material transfer warehouse in port | Lingju Flex variable spacing system + Graphite alloy pads | Single handling of 3 different diameter rolls, loading and unloading efficiency increased by 1150% |

Technical Parameters

Model | 180*50 | 180*80 | 370*180 | Non-standard customization |

Load Capacity | ≤5000kg | |||

Fork Length | 600-3000mm | |||

Stroke | According to customer requirements | |||

Speed | Loaded 45m/min | Unloaded 90m/min | ||

Acceleration | Loaded 0.5m/s² | Unloaded 3.0m/s² | ||

Positioning Accuracy | ±3mm | |||

Product Advantages:

High Efficiency and Energy Saving: Equipment energy consumption reduced by 30%, throughput increased by 50%+

Flexible Adaptability: Modular design, supports rapid expansion

Strong Stability: Industrial-grade standard, failure rate <0.1%

Data-driven: Full-process digitalization, supports AI predictive maintenance

Keywords:

Roll C4

RECOMMEND PRODUCT

Recommended Products

ONLINE MESSAGE

Online Message

If you have any suggestions, please leave a message or email us, and we will reply to you within one working day of receiving your message.

Contact Information:

13399555771 (International) / 4006786168(Domestic)

德尔盟

Email:

Delmeng Intelligent Equipment (Maanshan) Co., Ltd. is a high-tech enterprise focusing on the research and development, design, manufacturing, and sales of intelligent logistics equipment. The company's core product is telescopic forklifts, which are widely used in automated storage and retrieval systems (AS/RS) and other intelligent warehousing fields.

HUATAO GROUP

Online Message

If you are interested in us or our products, please feel free to leave us a message.